Replacing IEEE-1394 (Firewire) controller on main PCB of Nikon Super Coolscan LS-4000

This seems to be a relatively common failure mode of Nikon Coolscan LS-4000 ED scanners. The typical symptom is that scanner passes power-up initialization fine (no fast blinking), but is not recognized by a computer (in Windows - Device Manager does not see it). The scan software reports that it cannot find a scanner. Disassembly is fairly modest, but the IC repair is elaborate. The good news that the IC itself is cheap and readily available from Mouser, DigiKey and other standard suppliers.

Also, even if you do not think you have tools/skills to perform the IC replacement, you may be able to find a good electronics shop to do this for you...

Graeme Hardie (LincolnScan) in UK also performs repairs on Coolscan scanners, including firewire repairs.

1. Follow steps 1) through 12) in LS-4000 disassembly procedure. Remove the 3 screws in the step 12 and remove the metal PCB shields.

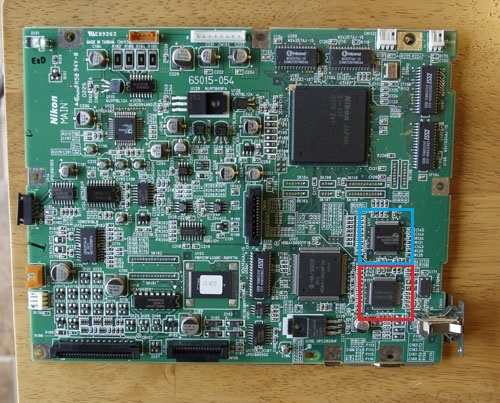

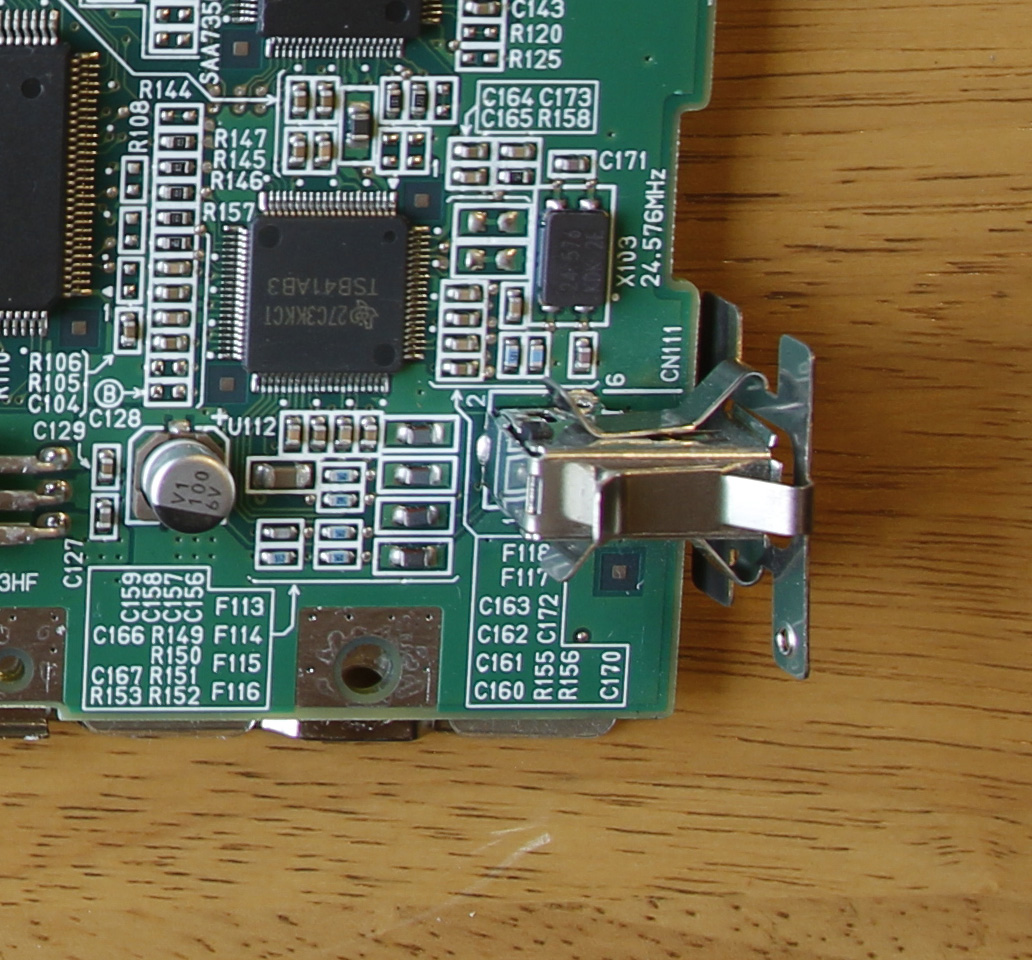

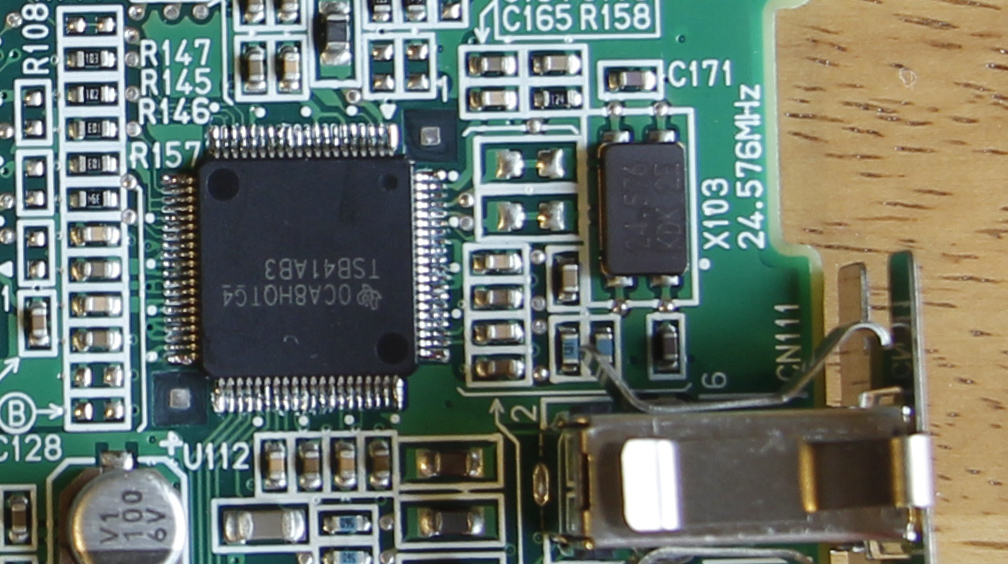

2. The chip inside the red box is the Firewire controller IC that had most likely failed in the case of the above symptoms. The IC is made by Texas Instruments, part number TSB41AB3.This IC is surface mounted, the package type is HTQFP80. The chip inside the blue box is 1394 SBP-2 link layer controller IS, made by Phillips (NXP), part number SAA7356HL, the package type LQFP80.

Below is the procedure for replacing the TSB41AB3, the procedure for replacing SAA7356HL is the same

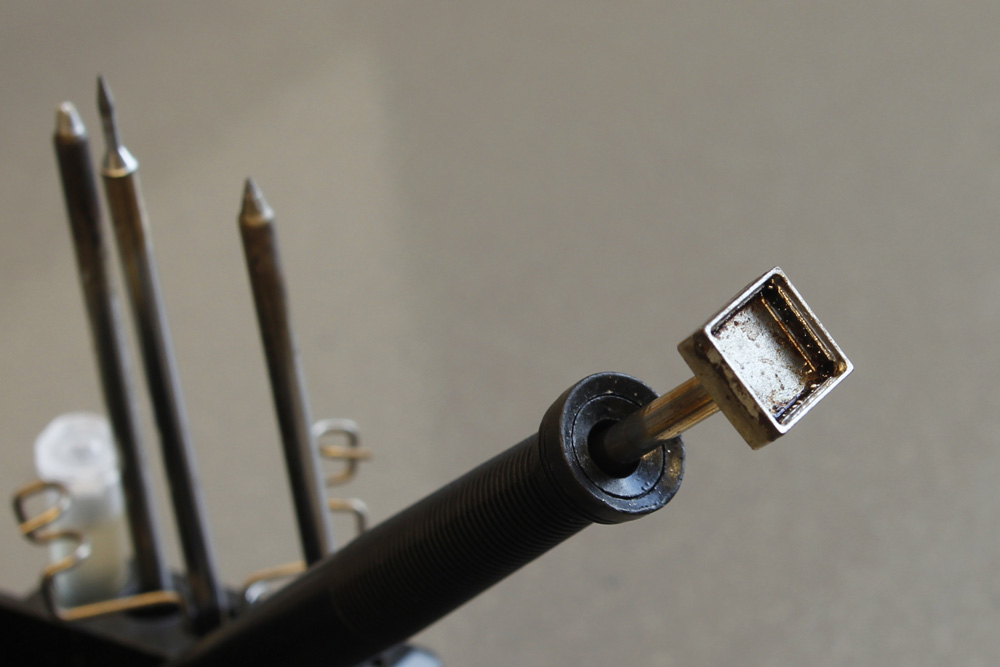

You can remove this IC using a soldering iron with a special tip designed to remove such surface mounted IC's, for example OKI-Metcal SMTC-115 de-soldering tip (for use with OKI MX-500 or MX-700 soldering station - see below).

If you do not have such de-soldering station, you can very carefully cut each lead with a razor blade (be careful - make sure you cut as close to the plastic IC case as possible and do not cut into the PCB itself) and then de-solder the leads and clean the PCB with regular soldering iron and de-soldering wick.

Shown above is a PCB with replaced Firewire controller. I am sure you can do a better soldering job, good luck!

Update:

Overtime, I had

performed few of these fixes – and had few failures.

I think that unless you are really good at replacing surface-mount components –

the replacement may have weaker thermal contact to the PCB and may get hot after

some time during the operation. If the IC is not rated to work at higher

temperatures this may result in the intermittent failures. The scanner would

work for about 15 min to 1 hour, and then the computer would stop recognizing

it. If I shut it down for an hour and then turn back ON - it would work again –

but then would stop again after some time.

(This may also

indicate initial weak point of the design - the fact that this failure is fairly

common may mean that the chip is not heat sunk sufficiently.)

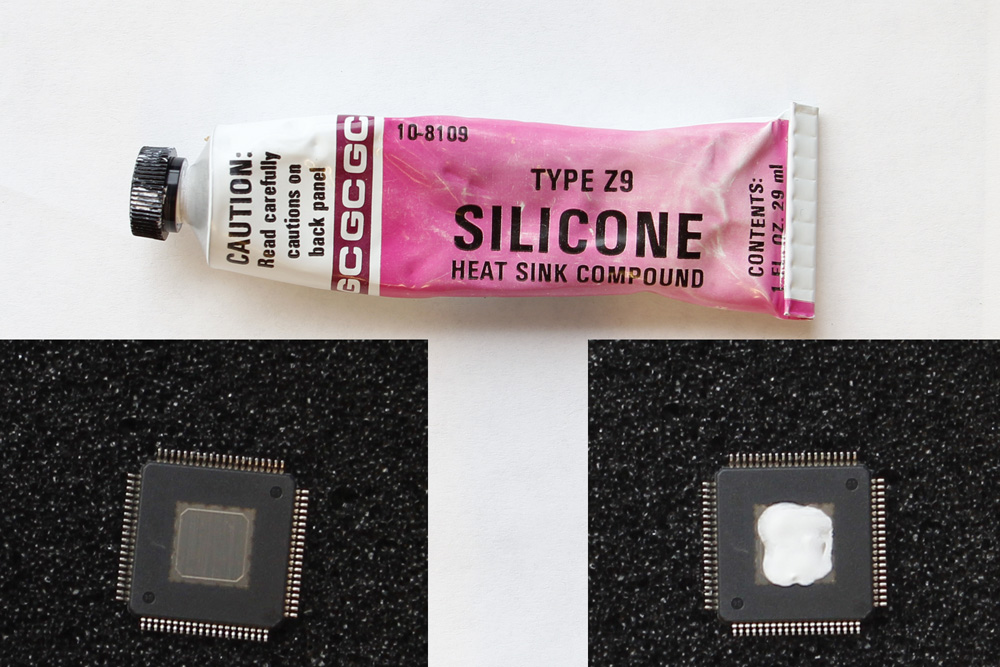

Assuming that the temperature of the replacement chip was a cause, I started

using the part that is rated to work at higher temperature – up to 85C

(usual military spec), and also adding a little bit (make sure it is just a little bit!) thermal heat-sinking compound between the replacement IC and the PCB (similar to what they use when mounting heat-sink fans on the processor chips on computer motherboards - see below).

I have not had any failures with these – may be I am lucky, may be it is a better IC, or may be I am right :).

Update: the note above in italic is probably incorrect. I had stopped using military speced components (I could only find them for TSB41AB3 anyway). I think the repeat failures of the past were mostly because I would only replace one IC. Now I always replace both IC's and have far lower repeat failure rate.